When producing plastic components, it is important to control the humidity level in the material and in the air during the process to ensure high quality in the end product. Today this is a very energy consuming process.

Airwatergreen AB is continuously looking for new innovations and working to help other companies improve their methods and processes. Together with the Dutch-based company Piscatio BV, a project has been initiated for the plastics industry.

Many plastic compounds need to be dried before they can be processed further. This is due to the fact that the moisture in the compound used in the production can produce bumps and holes in the end application.

This international project was started to investigate the possibility to dry plastic compounds with the lowest possible energy consumption. This would result in a more sustainable application in comparison to the conventional drying equipment with continuous heated air using much more energy.

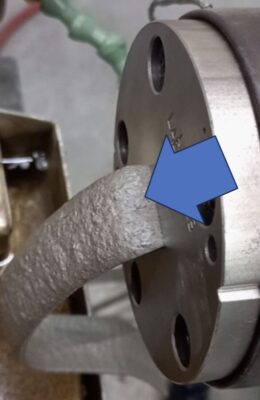

In the experiments, a vessel is filled with compound and connected to the REX (see picture at the top) to reduce the amount of water at the compound.

Compound samples are tested before and after the process by measuring the moisture content. Energy consumption is continuously monitored during the process.

The Airwatergreen REX dehumidifier is typically used to dehumidify the indoor climate with the lowest possible energy consumption. The low energy consumption of REX is achieved thanks to the patented technology used in the dehumidifier.

The project is subsidized by #LIOF and is carried out in collaboration with #Meldon Plastics BV and #DM&P BV.

The aim of the test is to evaluate how to create an energy-efficient production process that ensures high quality in the process.