Pressure stations

The task of the booster station is to increase the pressure in the transportation of drinking water over a distance.

Roles of a pressure station

The stations are built both above ground and underground. The stations are designed to meet current flow and pressure rise requirements.

Pressurization requirements can vary from small systems for remote communities to separate pressurization zones in cities that ensure rapid responses to contamination scenarios.

The challenge with pressure stations is that condensation easily forms on the surface of the cold pipes in the station. Even if the air feels dry, there is water in the air.

Warm air holds more moisture than cold. This causes the moisture contained in the “dry” air to precipitate on the pipes, which are often at a temperature below 10°C. This temperature is then the dew point and it is this that determines the relative humidity (RH) level that must be maintained.

Warm air holds more moisture than cold. This causes the moisture contained in the “dry” air to precipitate on the pipes, which are often at a temperature below 10°C. This temperature is then the dew point and it is this that determines the relative humidity (RH) level that must be maintained.

Many heat their stations to reduce the relative humidity level. It usually helps against mold in the station – but not against corrosion because heating does not remove the water from the air.

Our recommendation is to lower the heat in the station and instead let the cold pipes become the surfaces that heat the room when it is cold outside. This requires a dehumidifier that regulates the amount of water in the air and is equally effective at lower temperatures. In this way, you can reduce your energy costs and your CO2 impact.

Profitability calculation

Heating using a typical electric element consumes between 10,000 – 12,000 kWh per year based on the data we have available. On average, an Airwatergreen dehumidifier consumes significantly less than 3,500 kWh per year. Just under 2,000 kWh in the installations measured by customers. This results in energy savings of between 8,000 – 10,000 kWh per year! This is typically equivalent to the same amount of money if you consider a cost of electricity of 1kr/kWh. That’s around half a million per year if you have 50 stations in operation!

Plus, of course, you reduce the cost of renovation by eliminating corrosion, damage to electronics and mold!

The right relative humidity level

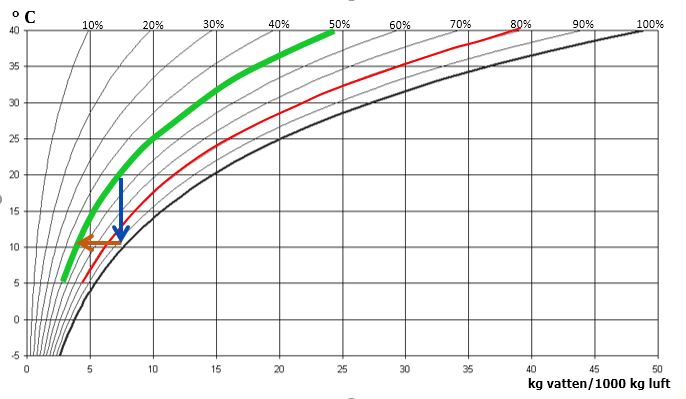

What is needed is a controlled moisture level below 60% (RH) to avoid corrosion and mold. This requires controlled relative humidity at the temperatures that can cause condensation on the cold pipes – not in the rest of the air. See the Mollier diagram where the condensation (saturation) curve is indicated as 100% RH at different temperatures.

In the example above, you can see that the relative humidity level goes from 50% to almost 100% when the temperature is reduced from 20C to 10C.

We recommend using an external dew point sensor connected to our dehumidifier for pressure boosting stations. It then senses the temperature of the coldest surface in the room (the pipes) and controls the dehumidifier to remove as much water from the air as possible to prevent condensation.

Easy installation

We don’t need to run any unnecessary ventilation pipes. Our dehumidification technology is equally energy efficient in cold and warm spaces. The dehumidifier can be mounted on a wall bracket that allows it to be easily mounted on the wall, keeping the floor free in the station building. A standard 1-phase 230V plug is enough to get you started.

The easiest way to get rid of the water is with a hose to a floor drain or other outlet. If there is no drainage, a collection vessel or pump can be used to remove the condensate.

Airwatergreen currently has a large number of installations in booster stations. In some cases the dehumidifier works independently towards the set dew point and in other cases it is connected to the existing monitoring system.

The FLEX dehumidifier dehumidifier is built to withstand harsh environments with thoughtful material choices and an IP63 rating.

The air passing through the dehumidifiers is not only dehumidified but also filtered to capture dust and insects. This creates the conditions for a good working environment!

Product selection

Our smaller dehumidifier is called FLEX and has a capacity of 5 liters of water/day, which is more than enough in a normal sized booster station.

Our smaller dehumidifier is called FLEX and has a capacity of 5 liters of water/day, which is more than enough in a normal sized booster station.

A typical configuration includes:

- Dehumidifiers FLEX type Smart or FLEX Integrate

- Wall bracket

- Dew point sensor

- Service contracts

References

Airwatergreen currently has a large number of installations in booster stations. In some cases the dehumidifier works independently towards the set dew point and in other cases it is connected to an existing monitoring system that either monitors the dehumidifier only or controls it.

The products are built to withstand the harsh environment with few moving parts and well thought out material choices and an IP63 rating.

The products are built to withstand the harsh environment with few moving parts and well thought out material choices and an IP63 rating.

The air passing through the dehumidifiers is not only dehumidified but also filtered to capture dust and insects. This creates the conditions for a good working environment!